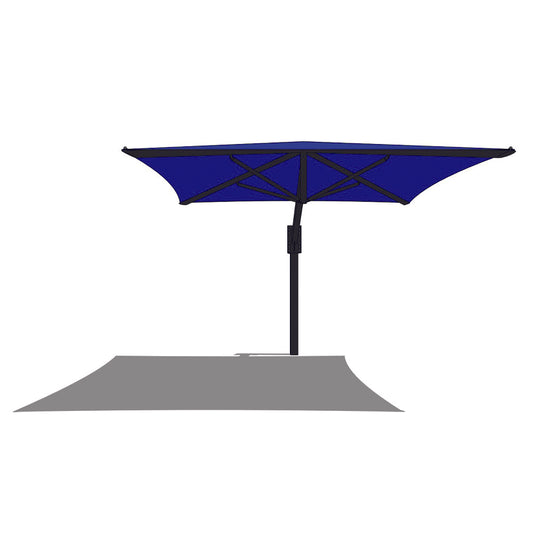

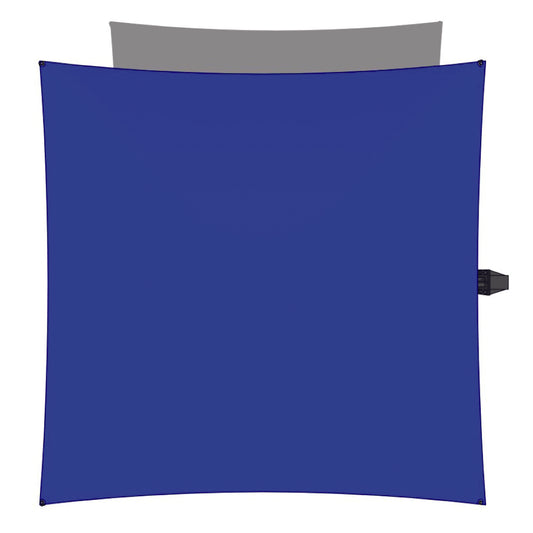

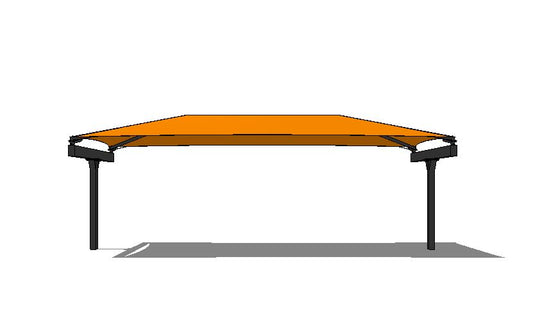

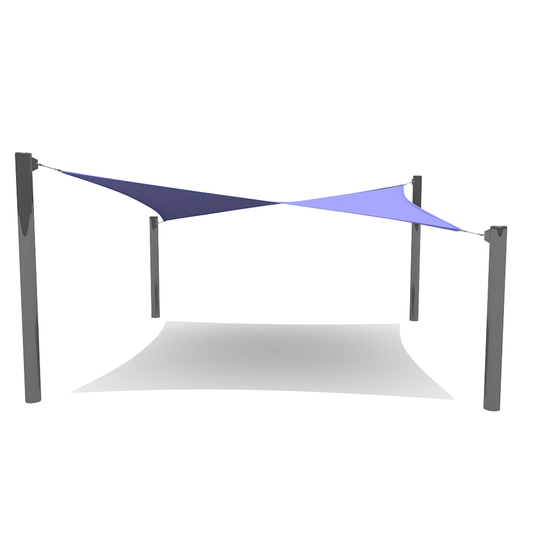

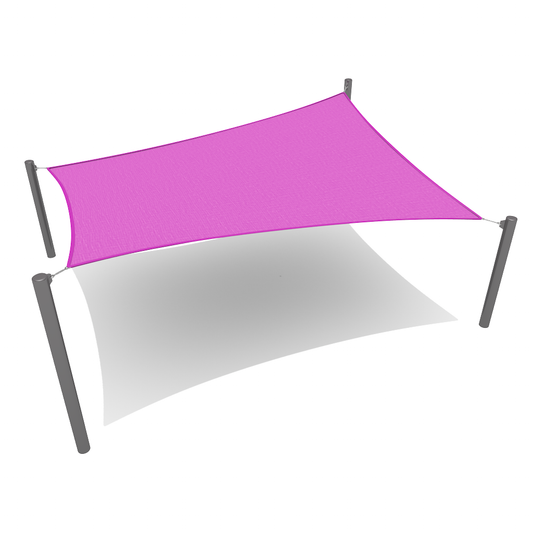

Full Hip

Full Hip

A very popular choice for the recreational market, these structures can also be utilized for a wide variety of applications from play areas, to parking areas, and much more.

Couldn't load pickup availability

Installation

Installation

We Offer Installation!

We are excited to offer installation services across most of the contiguous state of Texas. In order to obtain a quote, please email, call, or simply add the product of your choice to a quote, fill out a little information and be sure to check the box to request installation pricing. For installation, be sure the area is free of debris and any underlying issues that would make digging difficult. Each customer takes responsibility for their own site prep, permitting, and mulch/surfacing unless otherwise arranged. We do not take responsibility for permitting — you should consult your local authorities or construction professionals as needed.

In Ground Mount– In Ground Mount is the most common system. That is when you bury the pole directly into the ground using rebar and concrete.

Surface Mount – Surface Mount is mounted and bolted directly to a stable and solid surface. This approach would be ideal for a concrete pad or a pool area, for example. Anchor bolts and plates are generally required for this footer type.

Anchors– Anchoring to an existing structure such as posts, buildings, and roofs is only recommended for small tension projects.

Fabric Specifications

Fabric Specifications

| Yarn | Knitted UV-stabalized HDPE |

| Construction | Monofilament & tape |

| Pattern | Lock-stitch knitted |

| Temperature range (C°) | -30 to +70 |

| Approximate thickness (mm) | ~1.6 |

| Tensile strength- warp(N/50mm)(AS 2001.2.3.1) | 670 N/50mm |

| Elongation at break- weft(%) (AS2001.2.3.2) | 117% |

| Wing tear-warp(mean) (AS2001.2.10) | 184N |

| Wing tear- weft (mean) (AS2001.2.10) | 347N |

| Burst pressure (kPa) (AS4878.5- Method B) | 3500 kPa |

| Burst force (N) (AS2001.2.19) | 1937 N |

| Flammability Index (range0-100) | 12 |

| Lead | Not detected |

| Pthalate | Not detected |

Steel Specifications

Steel Specifications

- Steel

All Reinforcement conforms to 60,000 psi ASTM A-42 Grade 60(excludes Super Spans and Tension

Cable Structures). Reinforcement steel, if required, is designed, detailed, fabricated and placed in

accordance with the latest ACI Detailing Manual (SP-66) and CRSI Manual of Standard Practice - Structural Steel

All steel tubing is triple coated for rust protection using the in-line zinc electroplating, Allied Flo-Coat®

process. Tubing is internally coated with zinc and organic coatings to prevent corrosion.

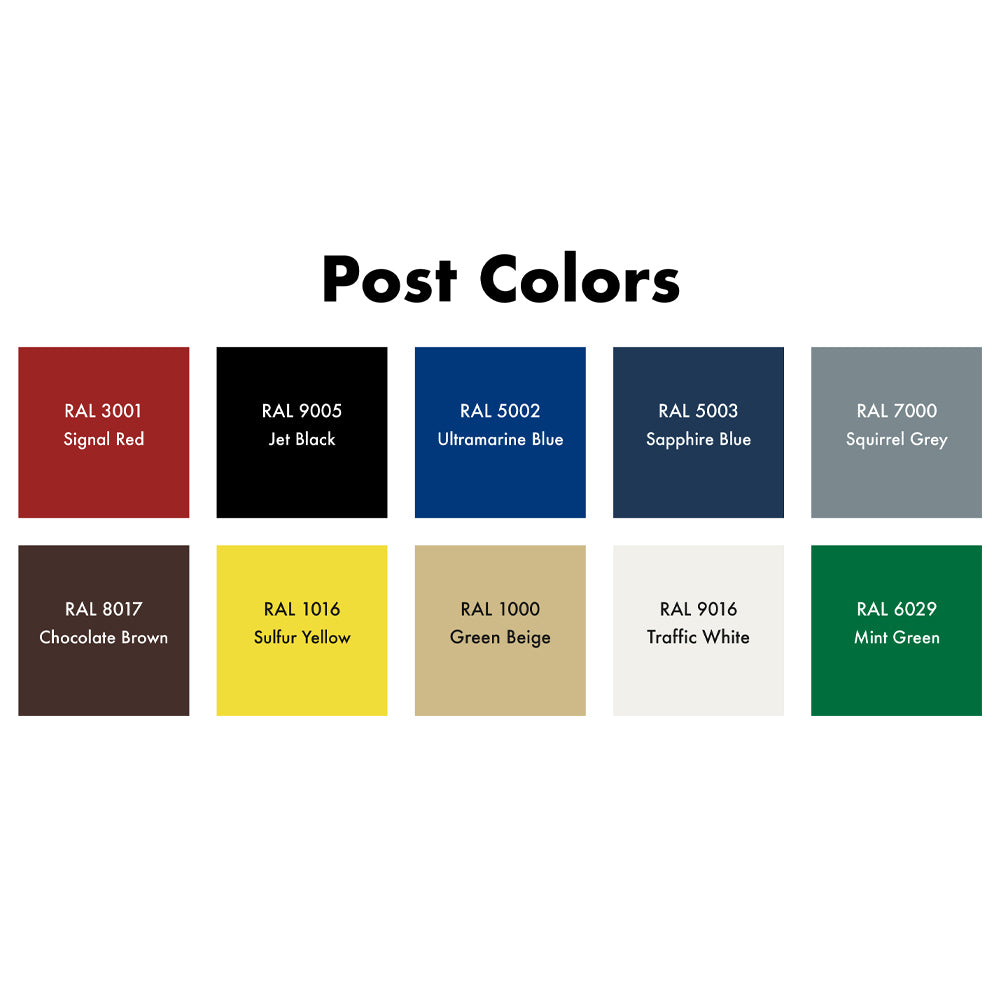

All structural steel plates are rust/corrosion treated by zinc electroplating. Steel tubing and plates are

finished with a minimum of 2.5 ~ 3.5 mil-thick UV-inhibited weather resistant powder coat.

Where size of structure or determined loads require larger structural steel members or steel greater than

7 gauge thickness, carbon steel may be substituted. Cleaning and coating of carbon steel conforms to the

following:

1. A de-greasing agent is applied to remove surface oil and grease.

2. An acid-phosphate wash be applied to etch and prepare the surface for powder-coating, where

wall thickness requires pre-heating.

3. Steel members are to be pre-heated prior to powder coat application to assure adhesion.

1. All carbon Structural Steel shall be ASTM A-36, except steel pipe columns, which shall be ASTM A-53,

grade B, unless otherwise noted. Slip fittings are manufactured using drawn-over-mandrel steel with a

minimum yield strength of 70 ksi and a minimum tensile strength of 80 ksi.

2. Steel telescoped sleeves do not have more than 1/16″ tolerance, with no less than 4″ overlap at all

sleeves. All internal fittings are welded on one side.

3. Structural steel is detail, fabricated, and erected in accordance with AISC specifications.

4. All shop and field welding is executed by certified welders in accordance with the latest edition of the

American Welding Society specifications.

5. Shop connections are welded unless noted otherwise. Field connections are separately indicated on all

drawings.

6. All welds are performed using E70 electrodes or gas-metal arc welding using ER 7053 wire. All fillet

welds are a minimum 3/16″ unless otherwise noted. All steel shall be welded shut at terminations to

prevent internal leakage. - Hardware

All structural field connections of the structure shall be designed and made with high-strength bolted

connections using ASTM A-354, Grade B or SAE J249, Grade 8

All stainless steel bolts shall comply with ASTM F-593, Alloy Group 1 or 2. All bolt fittings shall include

rubber washers for water-tight seals at joints. All nuts shall comply with ASTM F-594, Alloy Group 1 or 2.

Wire rope is 1⁄4″ nominal diameter, 7 strand, 19 wires per strand (minimum), with a minimum nominal

tensile strength of 9,000 pounds. Wire rope shall be secured with approved fittings and cable hardware, as

per manufacturers’ specifications.

Warranty

Warranty

Statement of Limited Warranty:

Shipping

Shipping

- Manufacturing lead-time from Company’s receipt of the “Notice To Proceed” is approximately 6 to 8 weeks for standard structures, and 8 to 12 weeks for custom structures. Delivery is approximately 1 week thereafter. Delivery of structures may be prior to or at the start of assembly. Please note that these timelines do not include approval or permitting timeframes.

- Once the item has shipped, you will receive a tracking number and important instructions for unloading. Ship dates are a best estimate and not guaranteed. Shipments can take up to 10 days in transit.

- Every order with complex shipping requirements receives shipping instructions.

Unless a loading dock is readily available, this equipment ships via curbside delivery. - Cantilever systems generally benefit from having a forklift for unloading, which is typical in the industry.

- There are many instances where the crates and pallets can be pulled apart by hand and unloaded as well, but a forklift is generally the quickest way to unload the product and is what trucking companies recommend to avoid possible detention charges (unloading that takes more than 3 hours).

- Please see our FAQ for more information.

Talk To An Expert

Talk To An Expert

Custom Structure

Custom Structure

Share

Features and Benefits

-

100% Recyclable

Unlike commercial textiles such as PVC, polypropylene (PP) and polyethylene (PE) products are fully recyclable.

-

Storm Approved

Engineered in Australia for the harshest conditions, fabric has a minimum 45 mph wind load and a 5 PSF Snow Load.

-

Shrink Proof + Mold Proof

Any possibility of shrinking is virtually eliminated due to our heat set fabric process. Strong HDPE won’t rot or absorb moisture.

-

10-Year Fabric Warranty

10-year UV degradation warranty on Gale Pacific 95 340 fabric.

-

Up to 98% UV Protection

UV-stabilized HDPE monofilament and tape yarn provides a UV Block range of 89.3%–98.2%.

-

Air Flow Channeling

Knitted lock-stitch construction for fray and tear resistance, offers more air movement and better channeling of cool breezes.

Applications

-

Car Park Covers

-

Playground Shading

-

Walkway Shading

-

Bus Stops

-

Seating Areas

-

Picnic Shading

-

Theme Parks

-

Water Parks

Related products

-

Four Sided Single Post

Regular price $0.00Regular priceUnit price / per -

T-Hip Cantilever

Regular price $0.00Regular priceUnit price / per -

Slanted Frame Cantilever

Regular price $0.00Regular priceUnit price / per -

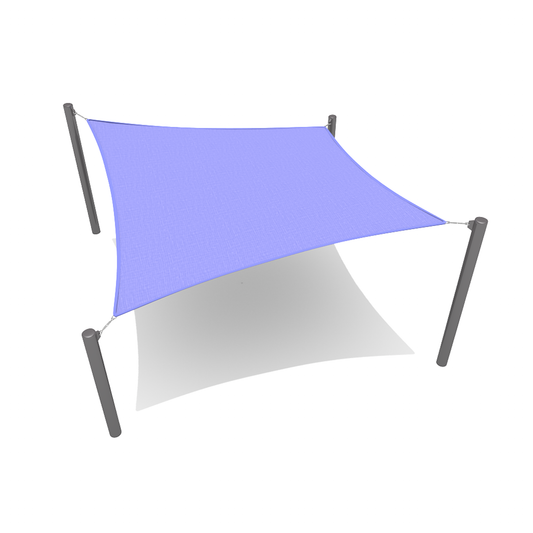

Square Shade Sail

Regular price $0.00Regular priceUnit price / per -

Rectangle Shade Sail

Regular price $0.00Regular priceUnit price / per